ポイント

- Data-sets from various systems are seamlessly ingested, managed, analyzed, and visualized.

- Daily routines optimized by 85%, and issues addressed earlier for 15% yield increase.

- KPIs visible across the business in real-time for operators, managers, and execs.

KX delivers performance visibility from the factory floor to the boardroom, supporting a strategic digitization initiative using data insights to reduce waste and improve output.

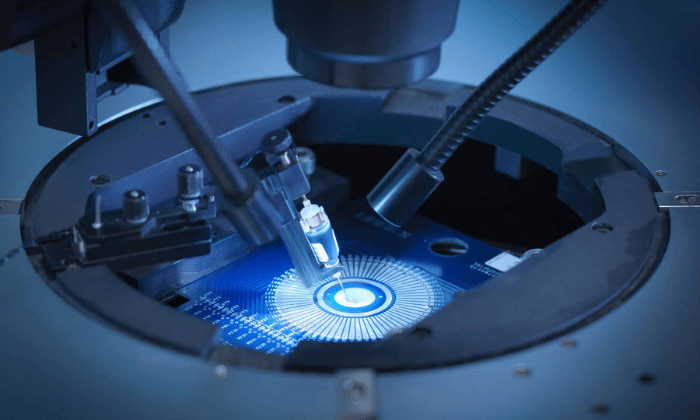

This manufacturer is a global healthcare technology leader with over 90,000 people across 150 countries, making innovative solutions that treat more than 70 health conditions. They combine technology and medical science to create solutions for less invasive surgical approaches and use insights from data to make substantial improvements in care, tailoring therapies in real-time.

They aligned architecture, infrastructure, and data solutions to support their global strategic initiative to digitize processes and deliver a better patient experience. Optimizing their manufacturing processes by providing data driven insight throughout the business has already proven to deliver a positive, measurable gain.

The challenge

Like every manufacturer, they needed to improve yield. They were striving to increase output and were keen to optimize their processes and resources, reduce costs, increase the visibility of KPIs across the business and build a foundation for future growth.

The manufacturer needed end-to-end visibility of productivity. And, they wanted to take it further and use real-time insights to inform and empower individual operators on the shop floor – where corrective action could be taken. They needed to improve product quality and establish more efficient processes – being alerted to issues for immediate redress rather than “too-late” reporting on a daily dashboard.

Why KX?

The KX integrated data management and streaming analytics platform uniquely ingests, stores, manages, analyses, and visualizes data from sensors and sources across multiple production lines and plants. This enables processes and quality to be continually monitored and optimized, efficiencies identified and implemented, and product failure and wastage reduced.

Operator performance is constantly measured and displayed through “pulse” lines on displays throughout the plant, with alerts and remedial actions proactively pushed to the point of-need.

With solutions tailored and adapted to the manufacturer’s specific needs, KX also helps them share productivity and performance data throughout the business – 60% faster than before deployment. Real-time insights are available to management for faster oversight, but with the ability to drill down onto particular issues or enrich with historical context to identify trend variation and help with future forecasting and the strategic digitization initiative.

Learn why businesses are choosing KX to help them make smarter decisions, optimize performance, and drive innovation. Or book a demo with our team