ポイント

- Semiconductor quality is protected in real time through a fast, reliable feedback loop—not after the fact through reporting.

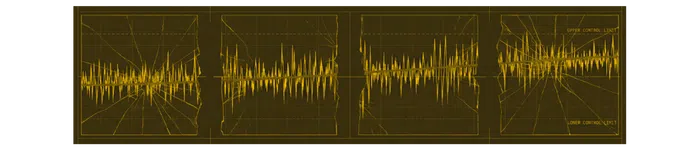

- FDC and APC performance depends first on complete, ordered, and trustworthy sensor data.

- High-frequency sensor signals only drive better decisions when aligned with the right operational context.

- Quality systems must be as scalable, resilient, and predictable as the production environment they support.

- Access to deep historical sensor data turns investigations into durable, repeatable process improvements.

In leading semiconductor fabrication plants (fabs), quality is won while the process is running. The best teams spot early signs of drift, contain excursions quickly, and capture what they learn so the same failure mode does not repeat.

Fault Detection (FDC) and Advanced Process Control (APC) help keep processes within limits. At scale, results can still be inconsistent, not because engineers lack expertise, but because the data and feedback loops are not built for factory speed and variability.

KX Sensors keeps the quality loop intact by capturing critical signals reliably, making them available for fast analysis, and maintaining the path from detection to action even when networks, tools, or workloads become unstable.

The quality challenge that is easy to underestimate

A fab is a high-variation environment with tight tolerances and expensive consequences. Tool behavior shifts by chamber, recipe, and condition. Materials drift. Sensors are noisy. Aligning signals with context across systems is hard. Small deviations can quickly result in yield loss.

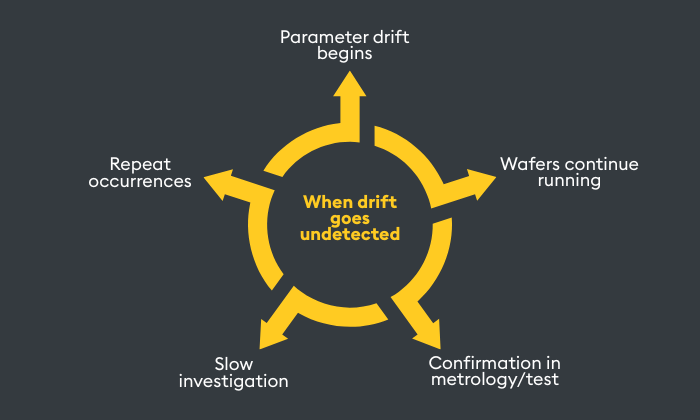

A familiar sequence follows:

- A parameter starts to wander, such as slower valve response, delayed temperature settling, or pressure oscillation.

- Wafers continue to run while the team decides whether the change is real.

- The issue is confirmed later in metrology, inspection, or test, when rework and scrap are far more costly.

- Investigation slows down because traces, events, and context must be pulled from multiple systems and aligned.

- The same event returns because the corrective action was not turned into a lasting control.

FDC is meant to catch deviations early. APC is meant to adjust control variables to keep the process on target. Both depend on the same prerequisite: sensor data that is timely, complete, correctly ordered, and available with the right context at production speed.

Why many quality loops break in practice

Across fabs, three patterns show up repeatedly:

Data gaps and disorder break trust

If a quality system cannot reconstruct what happened through network blips, load spikes, or restarts, engineers stop treating it as authoritative. Thresholds become conservative, manual checks return, and automation is used less.

Context is often harder than storage

Time-series traces only help when interpreted with tool state, recipe step, chamber identity, lot history, and recent behavior. Many stacks can store raw data but struggle to answer context-heavy questions quickly enough to drive decisions.

Quality infrastructure must run like production infrastructure

A real-time quality loop cannot depend on frequent babysitting, long maintenance windows, or fragile pipelines. It must remain predictable under load, degrade gracefully, and recover quickly because the factory does not pause.

How KX Sensors delivers performance at scale to strengthen quality decisions

KX Sensors is a streaming analytics stack designed for sensor-intensive operations where correctness and response time directly affect containment and yield.

In practice, customers consistently point to performance at scale as a key enabler of better-quality decisions. KX Sensors delivers markedly faster trending, querying, and data access on sensor data, which shortens investigation cycles and reduces engineering time spent waiting on systems. Teams can explore signals, test hypotheses, and act while conditions are still relevant, rather than after the window for containment has passed.

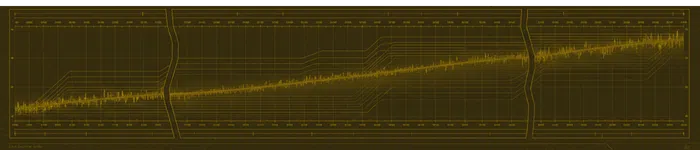

More importantly, fabs highlight the ability to work with large volumes of historical raw trace data as a decisive differentiator. Instead of breaking history into short analysis windows, KX Sensors supports efficient analysis across long time horizons of high-frequency data in a single workflow. This makes it possible to learn from months of past behavior, identify subtle patterns, and turn historical insight into more durable controls.

Many analytics tools fracture history into disconnected analysis windows. When data is chopped into small time buckets, the long-term pattern of drift is severed and hidden.

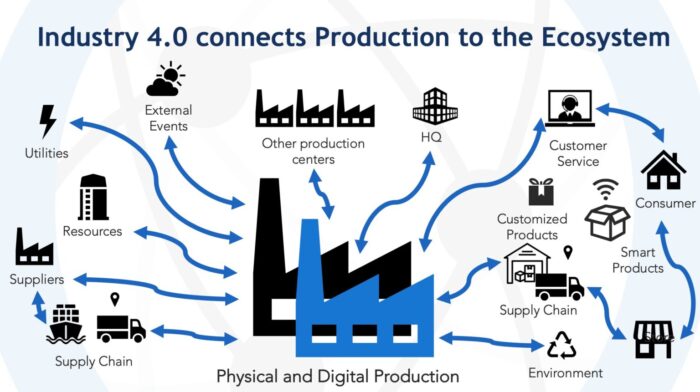

As part of the Product team working closely with industry-leading fabs and OEMs, I’ve seen how the capabilities below map to common FDC and APC needs and support broader Smart Factory quality goals such as correlation, auditability, and repeatability.

- Lossless ingestion and consistent ordering: FDC and APC require a time-series record that is complete and ordered. When streams drop samples or arrive out of order, models and controllers can respond incorrectly. KX Sensors is designed for lossless capture with ordering guarantees so teams can tune detection with confidence.

- Decoupled ingestion that scales with the factory: Quality workloads grow as more tools, sensors, and derived signals come online. KX Sensors includes a distributed, persisted messaging layer that decouples producers from consumers. This helps ingestion and downstream analytics scale independently while keeping delivery reliable.

- Handling late-arriving data without expensive rewrites: Late data happens in real factories. Instead of rewriting large partitions, KX Sensors can store very late-arriving data in lightweight delta tables and automatically merge it at query time. This preserves a consistent view while improving write performance when late data is a small fraction of a partition.

- Fast access to real-time data and the right historical window: Many decisions require quick context: Is a spike unusual for this recipe step? Has this chamber shown similar behavior recently? KX Sensors supports low-latency querying across recent and historical windows so detection can move beyond simple thresholds toward higher-precision decisions.

- Query routing that keeps urgent workloads responsive: Detection workloads compete with dashboards, investigations, and ad hoc analytics. KX Sensors supports scalable query services and intelligent routing based on factors such as data location and load. This helps maintain responsiveness for real-time workloads even as usage grows.

- High availability, recovery behavior, and data integrity guarantees: Quality infrastructure is most valuable during instability, which is also when systems are most likely to fail. KX Sensors supports high availability architectures with standby takeover. RAFT-backed reliable messaging framework and checkpointing help protect integrity during failures by preventing duplicates and minimizing data loss.

- Master data and audit-ready history: Quality decisions depend on master data, such as tool identifiers, chamber mappings, recipe metadata, and limits. KX Sensors includes an MDL framework to manage master data changes with validation and consistency controls. For domains that require historical truth, bitemporal table support helps track both event time and system time for precise audit views.

What changes for fault detection

FDC has two goals: catch excursions early and keep alerts usable.

With complete, ordered data and faster contextual queries, detection can safely use more sensitive features such as trends, slopes, oscillation, and multi-signal relationships. Context-aware logic can also reduce false alarms by using step-specific baselines and recent history.

When an excursion does occur, faster retrieval and alignment of the right traces and events reduce time-to-understanding. This makes it easier to convert investigation outcomes into durable controls and workflows.

What changes for advanced process control

APC depends on stable access to consistent signals, especially in 24 x 7 operations. When the pipeline is predictable and trusted, controllers can often run with tighter margins without increasing risk. That improves uniformity and reduces rework.

A shared, consistent data record also improves coordination between detection and control. Detection flags abnormal conditions. APC corrects where it can and triggers containment when it cannot. Fewer disagreements between what was observed and what was done improves learning over time.

Why this matters for OEMs

OEMs do not just build capability. They ship it across many customer environments with different constraints. A dependable embedded layer reduces support burden and lets OEMs differentiate through domain logic, workflows, and UI.

KX Sensors focuses on the infrastructure problems that commonly derail quality initiatives: reliable ingestion, predictable query behavior, high availability, operability, and deployment options that fit constrained environments.

Quality is a feedback loop, not a report

Modern quality comes down to four actions: detect early, decide with confidence, act quickly, and capture what you learn. That loop works only when sensor data is treated as mission-critical, served fast, and preserved with integrity.

KX Sensors helps fabs and OEM partners drive repeatable, scalable quality outcomes using FDC and APC on high-frequency sensor streams. Learn more here.