Hi-Tech Manufacturing

Optimize productivity and uptime with real-time, IOT-powered analytics.

Enhance machine production lines and uptime on the factory floor.

Smart manufacturing is grappling with the challenges of fast data and the critical need to optimize processes and maximize yields. Legacy analytics platforms hold back many organizations, including:

Handling diverse data sources

Integrating structured and unstructured production data is challenging, hindering comprehensive analysis and insights.

AI-driven quality insights

Siloed data prevents effective defect detection, increasing waste, rework, and inconsistent product quality.

Real-time process optimization

Manufacturers need help to address inefficiencies quickly, as legacy systems can’t process real-time data fast enough.

Predicting equipment failures

Fragmented data sources reduce the accuracy of predictive models, leading to costly, unplanned downtime.

Why hi-tech manufacturing organizations choose KX

Smart manufacturing: Predictive maintenance, productivity, and efficiency insights:

Data integration

Unify diverse data sources for comprehensive analysis and actionable insights.

Predictive maintenance models

Integrate data streams to predict and prevent equipment failures.

Real-time analytics

Deliver instant data processing for faster decision-making.

Scalable system

Support the ever-growing number of tools, sensors, and measurement frequencies.

Optimize processes

Ensure consistent quality control and reduced waste with advanced analytics.

Analytics on demand

Delivers analytics on the factory floor, in the data center, and the cloud.

How we help

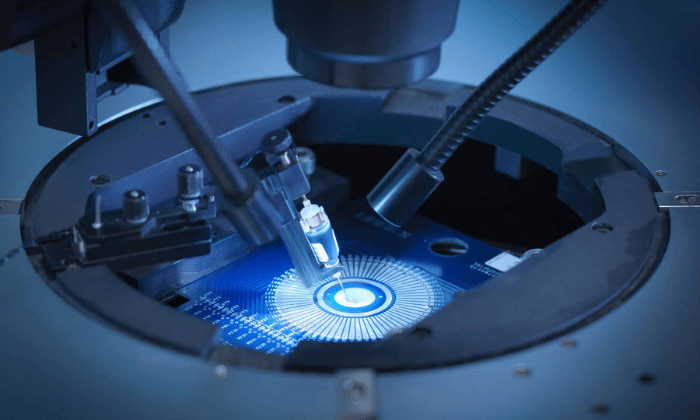

PREDICTIVE MAINTENANCE

Proactive fault detection and optimized uptime

Integrate real-time sensor data with historical maintenance records, predicting equipment failures before they occur. This reduces downtime, extends machinery lifespan, and optimizes maintenance schedules.

YIELD MONITORING AND OPTIMIZATION

Faster control decisions to optimize production

Analyze data from sensors and production systems to track yield metrics, identify inefficiencies, and optimize resource allocation, ensuring higher output with lower waste.

VISUAL QUALITY INSPECTION

Insights from unstructured data

Process high-resolution images and correlate them with production data to detect real-time defects. This minimizes waste, reduces rework costs, and ensures consistent product quality.

DIGITAL TWINS

Accelerate cost-reducing process simulations

Combine data streams to simulate, monitor, and optimize production in real time using digital twins. This enables you to test scenarios and enhance operational efficiency.

AIによるイノベーションを加速する、KXのデモをお客様に合わせてご提供します。

当社のチームが以下の実現をサポートします:

- ストリーミング、リアルタイム、および過去データに最適化された設計

- エンタープライズ向けのスケーラビリティ、耐障害性、統合性、そして高度な分析機能

- 幅広い開発言語との統合に対応する充実したツール群

専門担当者によるデモをリクエスト

「*」は必須フィールドを示します