By Bill Pierson (Originally published as a SEMI Blog)

Demand for hi-tech manufactured goods is at an all-time high and is expected to grow significantly in our new digital age, COVID-19 economy. This is especially true for semiconductor chips. Chip manufacturers have been working to meet this demand by building new factories and by optimizing processes and equipment in existing fabs.

While there is much media coverage about new factories planned by leading-edge chipmakers and government investments in the semiconductor sector, greenfield fabs entail significant capital expenditures and are sometimes fraught with complex political concerns. As a result, they can take several years to complete and reach their planned production capacity.

Instead, the semiconductor industry needs to optimize existing factories in order to increase productivity and yield and meet growing demand by implementing smart manufacturing solutions. Smart manufacturing solutions will inherently reduce costs with more efficient and automated processes, and those savings can be reinvested for the next wave of solutions.

Chip Industry on the Bleeding Edge

Semiconductor manufacturers have always been focused on bleeding-edge technology to outflank strong competition and build the best products – faster and cheaper. Today, pioneering organizations are using data to optimize manufacturing processes and equipment, a practice known as Smart Manufacturing.

“Smart manufacturing is an essential asset to operate a modern fab and may be even more important to sustain an established one.”

Thomas Richter, VP & Fab Manager, BOSCH

While there are many definitions of Smart Manufacturing, the essence is maximizing the utility of big data generated in these factories by leveraging three pillars: Sensing, Connecting, and Predicting. It is not just the digitization in manufacturing, but it is also about turning the data into actions that generate value – an effort the SEMI Smart Manufacturing Committee is driving based on the three pillars. Optimizing return on investment is the ultimate goal.

Fig. 1 SEMI Smart Manufacturing Initiative activity is based on three pillars that support the goal of increasing ROI.

Making the Right Decision, Faster

Smart manufacturing practices enable organizations to make the right decisions and take action faster based on insights generated from real-time and historical data. This requires data management technologies and applications that can process, analyze, and act on information instantly.

It has become ever more difficult to process and discern the relevant data or signal from the vast volume of data, perform analytics or develop new ML or AI analytic tools, and then make the critical decisions to solve problems as close to real-time as possible.

Who’s Responsible – IT or OT?

In the past, IT (Information Technology) and OT (Operations Technology) were separate entities within organizations, with IT focused on storing large amounts of data for enterprise systems and OT concentrated on using data to perform specific functions. Smart Manufacturing often demands combining IT and OT, difficult in rigid organizations that operate the two organizations independently and lack the infrastructure to implement comprehensive solutions. Success requires executive leadership sponsorship, motivated technical personnel and, most importantly, a clear deliverable on the value in implementing Smart Manufacturing.

Many organizations have introduced top-level leadership positions such as a Chief Information Officer or Chief Data and Analytics Officer to address this convergence and many of these leaders are embracing Smart Manufacturing practices.

The SEMI Smart Manufacturing community includes many of these leaders and therefore has highlighted the importance in the return on investment for Smart Manufacturing solutions. Read more about IT and OT convergence and note that Smart Manufacturing is synonymous with Industry 4.0.

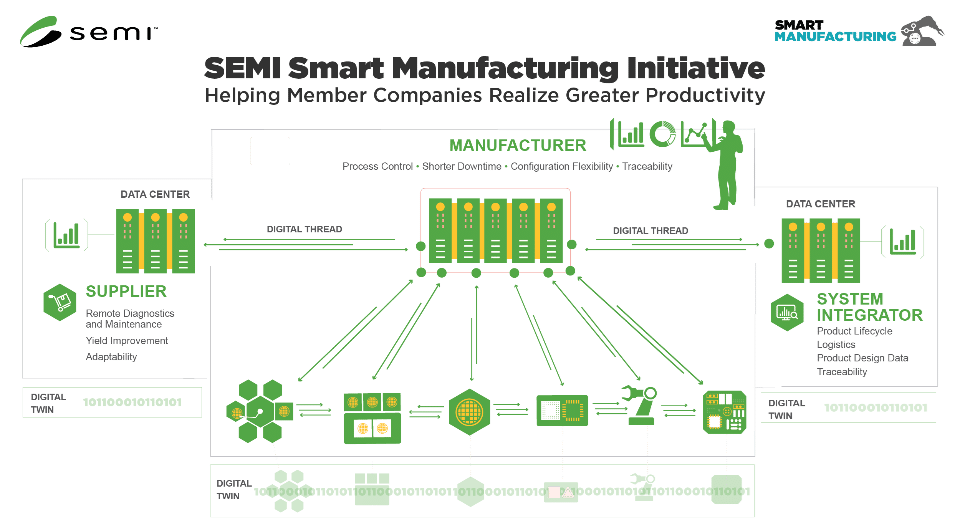

The SEMI Smart Manufacturing Initiative covers the entire supply chain.

Get Smart in Smart Manufacturing

While new technologies and applications are being created to deal with mountains of data, it is the underlying methodologies and practices that are key to a successful Smart Manufacturing deployment. SEMI, the trade association representing the electronics manufacturing and design supply chain, is in a perfect position to evangelize Smart Manufacturing experiences and best practices for the entire manufacturing community. The more than 30 member companies participating in the SEMI Smart Manufacturing Initiative bring more than 500 years of collective experience and knowledge to the topic.

Many segments of the supply chain participate in the SEMI Smart Manufacturing Initiative including packaging, assembly, SMT and PCB assembly, test, software, data management, sensor and material suppliers.

Learn How to Manufacture Smarter

SEMI SMART Manufacturing is hosting two great conferences in the coming months – the Global Smart Manufacturing Conference (GSMC) and the SEMICON West Smart Manufacturing Pavilion. As a leader of the organizing committee and chair for the SEMICON West Smart Manufacturing Pavilion, I encourage people who want to learn how to implement Smart Manufacturing or expand their knowledge of Smart Manufacturing to attend these events.

The GSMC will feature keynotes highlighting the value of Smart Manufacturing, offer tutorials on the three pillars, and introduce several case studies for each of the pillars. Thirty-two organizations – ranging from global cloud providers, semiconductor factory operators, leading equipment vendors and software application solution companies – will present. See the full agenda here.

The SEMICON West Smart Manufacturing Pavilion will compliment GSMC by showcasing a number of use cases that highlight the value of Smart Manufacturing. Panel discussions will deep dive into the challenges of implementing these best practices and the direction smart manufacturing is taking in the coming years.

“Amkor uses real-time, in-process decision making to drive gains in quality, asset utilization and efficiency.”

Umesh Manathkar, Corporate VP and CIO, Amkor.

Our goal for these events is for you to take this knowledge back to your companies, implement and improve on the detailed solutions highlighted at the conferences, and return next year to share your success stories with the community.

See you soon, in person or virtually!

Bill Pierson is VP of Semiconductors and Manufacturing at KX, leading the growth of streaming data analytics in this vertical. Bill is also a chair for the SEMICON West Smart Manufacturing Conference and an active team member of the SEMI Americas Chapter. He has extensive experience in the semiconductor industry including previous experiences at Samsung, ASML and KLA. Bill specializes in applications, analytics, and control. He lives in Austin, Texas, and when not at work can be found on the rock-climbing cliffs or at his son’s soccer matches.