By Przemek Tomczak

Abraham Maslow’s wry observation that “if all you have is a hammer, everything looks like a nail” could unfortunately be applied to many cloud-migration strategies where there is a tendency to see centralized processing as the solution to every problem. But in some cases, reverting to the cloud is neither necessary nor indeed advisable. Consider a vehicle in motion and its embedded control systems: while some decisions such as best route to take may rely on external information and tolerate a reasonable time delay, others like whether to brake, accelerate or swerve to avoid an obstacle are based solely on information at hand and must be taken within milliseconds.

The same is true of decisions on the factory floor in relation to high performance tooling and systems. They cannot wait, and nor do they need to, for information from external systems or centralised services to determine next steps. It’s about making decisions locally based on information at hand. It’s about the using the edge, and using it intelligently.

What can be achieved at the Edge?

The concept of intelligence at the edge is not new, it was identified by Tim Bittman in Gartner some time ago and is gaining significant traction as its business benefits become increasingly apparent: improving quality by diagnosing problems faster, extending uptime by making corrective actions sooner, and saving costs by utilizing assets better. Specific examples of where edge intelligence has been introduced include:

- A fortune 500 engineering company running fault detection and statistical process control application deployed in factories used edge processing to improve query speeds over 50x, ingest hundreds of thousands to millions of sensor measurements per second and save over 10,000 hours of engineer-hours per year.

- As part of its Advanced Distribution Management system platform for monitoring and controlling power systems, Survalent uses edge computing to support new resources being deployed in power systems running utility sub-stations and control centers.

- A medical technologies company uses the edge for real-time visibility and analytics for OEE control, quality control and preventative maintenance in factories.

- An oil-gas field services company uses edges computing in mobile vehicles for real-time monitoring and analytics for improving the efficiency and effectiveness of drilling operations.

- Keysight’s Pathwave Manufacturing Analytics platform for factories is powered by edge processing

In each case above the edge engine is KX. This is why.

The challenge of Intelligent Edge processing

In order to determine the most appropriate action, and determine it instantly, an intelligent edge system needs data and lots of it. Its sources may include the multitude of sensors now available in the IoT world: chemical, biosensors, image, audio, speed, vibration, humidity, pressure, voltage, amplitude, location that, along with related context data (including master data and historical data) must be ingested, processed, and analyzed in the right place and right time. The right place is close to the data, the right time is now.

However, most IoT platforms and analytics solutions were not designed for local processing at that level of speed or sophistication. They are mainly storage systems with limited enrichment and analytics capabilities and rely instead on data being delivered to and from data central facilities far removed from where the response is needed, for advanced analytics. So, while cloud and central services are invaluable in general, the microseconds lost in moving data to the cloud and getting back the recommended action may render the result worthless in specific cases where the error has happened, the damage has been done, or the opportunity has gone. Achieving edge intelligence needs something extra.

KX Streaming Analytics platform

KX is an integrated lightweight platform providing data ingestion, processing, computation, analytics, visualization, and machine learning at both the edge and centrally in the cloud. It empowers intelligent systems and IoT platforms with high-speed, low latency data processing and historian capabilities while delivering data to cloud and on-premises data systems as needed. It integrates with IOT platforms and industry applications to move beyond store and forward to combined analytics of OT and IT data.

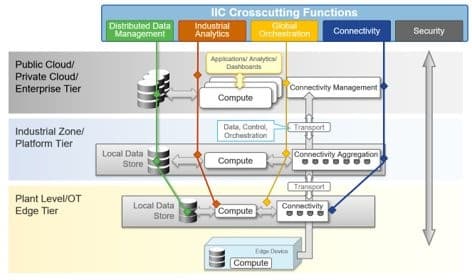

(Diagram courtesy of the IIC Consortium)

KX uniquely fits into the processing ecosystem across the three tiers above

- Capturing Data: Supporting growing data volumes – Large number of sensors and high frequency measurements (1 Hz to 100 KHz per sensor).

- Distributing Data: making data available to the right people, right systems, and right time

- Analytics: Joining asset and sensor data to MES, ERP, Asset Management data sources; Analytics and filtering data to detect faults and classify them for corrective and preventative action

- Delivering insights: Real-time analysis and results of sensor, processes and asset performance.

- Managing Data: Controlling the data lifecycle from ingestion and validation to persistence and ageing across appropriate storage tiers.

- Infrastructure & Energy Consumption: Running workloads as efficiently as possible within CPU, RAM, storage, power, and cooling constraints

These capabilities are delivered from a time-series, relational, and columnar database that includes built-in analytics libraries and a programming language for developing customised code and complex queries. It is delivered via a low footprint (<1MB) executable that imposes minimal infrastructure requirements and runs on Intel, ARM, and AMD CPUs, Linux, Windows, and MACOS.

Among the key feature of the platform that enable Intelligent Edge are

- Handles diversity of real-world data conditions including late, out-of-order and future data, validations, estimations, statistics, and notifications to deliver quality data for decision making

- Connectivity to and integration with popular languages, APIs, and industry standard protocols and equipment to enable reuse and reduce costs

- One run-time for analytics on edge, on-premises and cloud deployments reducing maintenance overhead

- Out-of-the-box accelerators for IOT and energy/utility use cases

- Dashboards for real-time monitoring and visualization of data and analytics

- High availability and fault-resilience

A recent partnership with Ori Industries, a global edge computing infrastructure firm, illustrates how these capabilities can be applied in reducing the decision-making window using real-time data analytics in the telco world. The integration of Ori’s Global Edge (OGE) platform and KX enables real-time in-stream analytics at the edge, significantly increasing the speed at which data can be analysed while also reducing the amount of data that needs to be sent to the cloud for processing. As commented by Douglas Mancini, Chief Commercial Officer at Ori Industries : “In pairing one of the industry’s fastest streaming analytics solutions with our low latency delivery stack we’re enabling telcos to leverage their networks like never before, opening up the true promise of 5G.”

That’s what intelligence at the edge can do.